The Concrete Reinforcing Steel Institute (CRSI) is a leading authority promoting best practices in reinforced concrete construction. Its Manual of Standard Practice is a cornerstone resource.

1.1 Overview of CRSI and Its Role in the Construction Industry

The Concrete Reinforcing Steel Institute (CRSI) is a leading authority in the reinforced concrete construction industry. Established to promote best practices, CRSI provides essential resources like the Manual of Standard Practice, which guides professionals in estimating, detailing, fabricating, and placing reinforcing steel. CRSI serves engineers, contractors, and specifiers, ensuring compliance with industry standards and improving project quality. Its efforts enhance efficiency, safety, and sustainability in construction, making it a vital organization for advancing reinforced concrete technology and practices globally.

1.2 History and Evolution of CRSI Standards

CRSI standards have evolved significantly since their inception, reflecting advancements in materials and construction techniques. The Manual of Standard Practice, first published in 1939, has undergone numerous updates to address industry challenges and innovations. Recent editions, such as the 29th, incorporate expanded bar placement illustrations and updated best practices for supports and epoxy-coated bars. CRSI’s standards are developed collaboratively with industry experts, ensuring they remain relevant and aligned with modern construction demands, while maintaining a commitment to safety, durability, and sustainability in reinforced concrete projects.

Understanding the Manual of Standard Practice

The Manual of Standard Practice is a cornerstone resource for the concrete construction industry, offering comprehensive guidelines for estimating, detailing, and placing reinforcing steel. It provides updated industry standards and best practices, ensuring efficiency and quality in construction projects.

2.1 Purpose and Scope of the Manual

The purpose of the Manual of Standard Practice is to provide a comprehensive guide for professionals involved in reinforced concrete construction. It covers essential aspects such as estimating, detailing, fabricating, and placing reinforcing steel. The manual serves as a reference for project specifications, ensuring adherence to industry standards and best practices. Its scope includes updated techniques, materials, and regulatory requirements, making it an indispensable tool for engineers, contractors, and specifiers aiming to deliver high-quality and durable concrete structures. The manual’s detailed illustrations and expanded sections on bar placement further enhance its practical application.

2.2 Key Features of the 29th Edition

The 29th edition of the Manual of Standard Practice introduces significant updates, including expanded bar placement illustrations for various reinforced concrete members. It doubles the coverage of topics like stainless steel reinforcing bars and includes updated errata addressing stirrup/tie hooks and bend shapes. The edition enhances clarity and practicality, offering detailed guidelines for estimating, detailing, and fabricating reinforcing steel. These updates ensure the manual remains aligned with current engineering practices, making it an essential resource for professionals in the field of reinforced concrete construction.

2.3 Importance of the Manual in Concrete Construction

The Manual of Standard Practice is a critical resource for ensuring compliance with industry standards and best practices in reinforced concrete construction. It provides comprehensive guidance for estimating, detailing, fabricating, and placing reinforcing steel, as well as repairing requirements. Professionals rely on it to enhance project efficiency, ensure quality, and adhere to safety protocols. By following the manual, stakeholders can mitigate risks and deliver durable, high-performance structures, making it indispensable for engineers, contractors, and specifiers in the construction industry.

Editions and Updates

The CRSI Manual of Standard Practice has evolved since its first edition in 1939, with the 29th edition being the latest. It undergoes regular updates to reflect industry advancements and corrections, ensuring it remains a vital resource for professionals in reinforced concrete construction.

3.1 Overview of the 29th Edition

The 29th edition of the CRSI Manual of Standard Practice is a comprehensive guide for reinforced concrete construction. It includes expanded illustrations for bar placements in various concrete members and updated standards for supports and epoxy-coated bars. The edition also covers technical updates on stirrup hooks and bend shapes, ensuring alignment with current industry practices. Professionals rely on this edition for detailed recommendations on estimating, detailing, and placing reinforcing steel, making it an essential resource for modern construction projects.

3.2 Recent Updates and Corrections (Errata)

The 29th Edition of the CRSI Manual of Standard Practice includes errata updates addressing key technical details. Corrections cover topics such as stainless steel reinforcing bars, stirrup/tie hooks, and bend shapes. These updates ensure compliance with current standards and industry best practices. Professionals are advised to review the errata to stay informed about revisions that impact project specifications and execution. Regular updates reflect CRSI’s commitment to maintaining the manual as a reliable and authoritative resource for reinforced concrete construction professionals.

3.3 Evolution of the Manual Over the Years

Since its first publication in 1939, the CRSI Manual of Standard Practice has evolved significantly. Early editions focused on basic standards, while later versions expanded to include detailed practices for estimating, detailing, and fabricating. The 29th Edition introduced enhanced illustrations for bar placement and expanded sections on epoxy-coated bars. Over time, the manual has incorporated advancements in materials and techniques, ensuring it remains a comprehensive guide for the reinforcing steel industry. Its evolution reflects the growing complexity and innovation in concrete construction practices.

Content Structure of the Manual

The manual provides detailed guidance on estimating, detailing, fabricating, and placing reinforcing steel, along with repair requirements, ensuring comprehensive coverage of industry standards and best practices.

4.1 Estimating and Detailing

The manual provides comprehensive guidance on estimating and detailing reinforcing steel, ensuring accurate material quantities and adherence to project specifications. It includes standard methods for calculating rebar requirements, detailed placement illustrations, and practical examples to streamline the process. The section emphasizes the importance of precise detailing to avoid construction errors and delays. By following these guidelines, professionals can ensure efficient and compliant designs, ultimately contributing to successful project outcomes. This section is essential for estimators, detailers, and engineers involved in reinforced concrete construction projects.

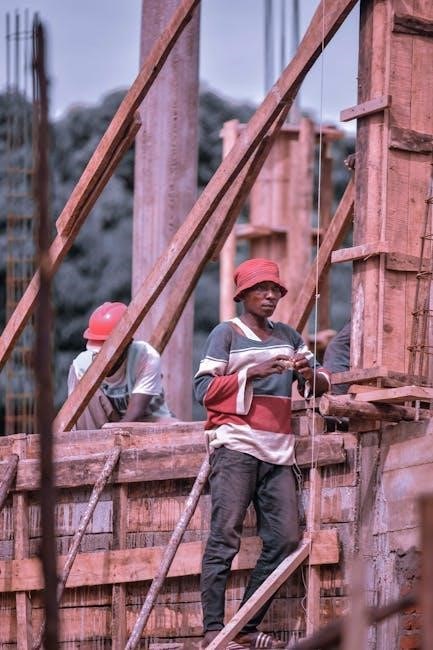

4.2 Fabrication and Placement of Reinforcing Steel

The manual provides detailed guidelines for fabricating and placing reinforcing steel, ensuring compliance with industry standards. It covers fabrication processes, including cutting, bending, and assembling rebar, and emphasizes proper placement techniques to maintain structural integrity. The section also addresses the use of materials like epoxy-coated bars and provides best practices for handling and installing reinforcing steel on-site. Additionally, it includes updated techniques for minimizing placement errors and optimizing material usage, ensuring efficient and durable concrete structures.

4.3 Repairing Requirements in Project Specifications

The manual outlines repair requirements for reinforcing steel in project specifications, ensuring defects are addressed before concrete placement. It covers common issues like surface damage and misplacement, providing methods for correction. The section emphasizes the importance of documenting repairs and adhering to quality control measures. By following these guidelines, professionals can maintain structural integrity and prevent costly rework, aligning with industry standards for durability and safety in concrete construction projects.

Technical Specifications and Standards

CRSI’s Manual of Standard Practice establishes technical specifications for reinforcing steel, including supports, epoxy-coated bars, and best practices, ensuring quality and safety in construction projects.

5.1 Standards for Supports for Reinforcement in Concrete

The Manual of Standard Practice outlines detailed standards for supports used in reinforcing concrete, including chairs, bolsters, and spacers. These standards ensure proper placement and alignment of steel reinforcement, critical for structural integrity. Topics covered include material specifications, allowable tolerances, and placement guidelines to prevent concrete cracking and ensure durability.

The manual also addresses load-bearing capacities and corrosion protection for supports, emphasizing their role in maintaining the longevity and safety of reinforced concrete structures. Compliance with these standards is essential for achieving optimal results in construction projects.

5.2 Specifications for Epoxy-Coated Reinforcing Bars

The Manual of Standard Practice provides detailed specifications for epoxy-coated reinforcing bars, emphasizing corrosion resistance. It covers material requirements, coating thickness, and adhesion testing. The manual ensures epoxy coatings meet durability standards for harsh environments, extending the lifespan of concrete structures. Compliance with these specifications is vital for maintaining structural integrity and preventing premature degradation of reinforcement in corrosive conditions.

5.3 Industry Best Practices for Reinforcing Steel

The Manual of Standard Practice outlines industry best practices for reinforcing steel, focusing on proper handling, storage, and installation. It emphasizes adherence to standards for bar placement, splicing, and corrosion resistance. Best practices ensure structural integrity, durability, and compliance with project specifications. The manual also highlights the importance of quality control and documentation to maintain consistency and safety in concrete construction projects. These guidelines are essential for achieving optimal results in reinforced concrete applications.

Material Properties and Bar Identification

The manual details properties of reinforcing steel, including strength and durability, and provides guidelines for bar identification through markings and testing, ensuring traceability and quality control.

6.1 Properties of Reinforcing Steel

The manual outlines the essential properties of reinforcing steel, including tensile strength, yield strength, and durability. It emphasizes the importance of understanding these properties to ensure proper material selection and structural integrity. Factors such as chemical composition and manufacturing processes are highlighted as critical influences on steel performance. The section also provides guidelines for testing and classification, ensuring compliance with industry standards. These properties are vital for achieving optimal results in concrete construction projects, making this section a foundational resource for professionals.

6.2 Bar Identification and Marking

The manual provides detailed guidelines for identifying and marking reinforcing steel bars to ensure traceability and quality control. Each bar is marked with essential information, such as the steel grade, bar size, and manufacturer’s identifier. These markings are critical for verifying compliance with project specifications and industry standards. The section also covers special markings for epoxy-coated bars and other corrosion-resistant materials, ensuring proper identification throughout the construction process. This standardized approach helps maintain consistency and reduces errors in material handling and placement.

6.4 Handling and Storage of Reinforcing Steel

Proper handling and storage of reinforcing steel are crucial to maintain material integrity. The manual outlines best practices, such as using suitable lifting equipment and avoiding improper bending or dragging of bars. Storage areas should be clean, dry, and level to prevent distortion or corrosion. Bars must be bundled securely and protected from environmental factors. Additionally, the manual emphasizes the importance of labeling and organizing stored materials for easy identification and traceability, ensuring compliance with quality standards throughout the construction process.

Splicing and Corrosion Resistance

The manual addresses splicing techniques, including mechanical and welded connections, ensuring structural integrity. It also highlights corrosion-resistant materials and coatings, essential for durability in harsh environments.

7.1 Splicing Bars: Mechanical and Welded Connections

The manual provides detailed guidance on splicing bars, emphasizing mechanical and welded connections. Mechanical connections are highlighted for ease of installation, while welded connections ensure high strength and durability. The 29th edition expands on techniques, including updated illustrations for clarity. Specific attention is paid to splice requirements in various concrete members, ensuring compliance with industry standards. Additionally, the errata addresses technical details such as stirrup hooks and bend shapes, enhancing the reliability of splicing methods in modern construction projects. Proper execution ensures structural integrity and long-term performance.

7.2 Corrosion-Resistant Bars and Their Applications

The manual highlights corrosion-resistant bars as a critical advancement in reinforced concrete construction. These bars, often epoxy-coated or stainless steel, are essential for structures exposed to harsh environments. Applications include marine structures, bridges, and areas with high humidity or chemical exposure. The 29th edition provides updated specifications and best practices for their use, ensuring durability and reduced maintenance. The errata includes detailed corrections on bend shapes and hooks, enhancing the reliability of corrosion-resistant solutions in challenging conditions. This ensures long-term structural integrity and performance.

Documentation and Reporting

Proper documentation is critical for traceability and compliance. Bar tags and mill test reports ensure material verification, while detailed records support project accountability and quality control measures.

8.1 Bar Tags and Mill Test Reports

Bar tags and mill test reports are essential for verifying the quality and specifications of reinforcing steel. These documents provide critical details about the material, including its grade, size, and chemical composition, ensuring compliance with project requirements. Mill test reports are generated by manufacturers, while bar tags are attached to the steel for easy identification on-site. Together, they serve as a permanent record, facilitating traceability and compliance with industry standards. Proper documentation is crucial for maintaining project integrity and accountability.

8.2 Record Keeping and Documentation Best Practices

Proper record keeping and documentation are vital for ensuring compliance, traceability, and accountability in concrete construction projects. The Manual of Standard Practice emphasizes maintaining detailed records of all reinforcing steel materials, including bar tags and mill test reports. Digital tools and secure storage solutions are recommended to organize and preserve documentation. Standardized processes for recording and updating project data help prevent errors and ensure transparency. Regular audits and reviews of documentation practices are essential to maintain accuracy and adherence to industry standards, ultimately supporting successful project outcomes.

Case Studies and Practical Applications

The Manual of Standard Practice includes real-world case studies demonstrating its practical application in concrete construction, offering insights into problem-solving and best practices implementation.

9.1 Real-World Examples of Manual Implementation

The Manual of Standard Practice is illustrated with real-world examples, showcasing successful implementations across various projects; These case studies highlight efficient estimating, detailing, and fabrication processes. For instance, a recent project utilized the manual’s guidelines to optimize bar placement, reducing construction time by 15%. Another example demonstrated how adhering to the manual’s standards improved durability in high-corrosion environments. These practical applications underscore the manual’s role in enhancing project efficiency and quality in concrete construction.

9.2 Lessons Learned from Industry Projects

Industry projects highlight valuable lessons from implementing the CRSI Manual of Standard Practice. Real-world applications have shown how adhering to the manual’s guidelines enhances project efficiency and durability. For instance, proper bar identification and handling practices have minimized errors, while corrosion-resistant bars have improved long-term structural integrity. Challenges, such as complex detailing requirements, have been overcome by leveraging the manual’s recommendations. These insights emphasize the importance of staying updated with the manual’s standards to ensure optimal outcomes in reinforced concrete construction projects.

Technical Resources and Support

The Manual of Standard Practice is supported by CRSI’s extensive technical resources, including webinars, training programs, and design guides. Members gain access to the latest errata and updates, ensuring compliance with industry standards. CRSI also offers publications and educational opportunities to enhance professional development in reinforced concrete construction.

10.1 Accessing the Latest Errata and Updates

The Manual of Standard Practice is regularly updated to reflect industry advancements. The 29th edition’s errata, including updates on stainless steel reinforcing bars and bend shapes, can be accessed via the CRSI website. Members receive notifications through newsletters and have exclusive access to technical resources. Additionally, CRSI provides corrections and clarifications online, ensuring professionals stay informed. Regularly checking the CRSI portal or subscribing to updates is essential for maintaining compliance with the latest standards and best practices in reinforced concrete construction.

10.2 CRSI Publications and Design Guides

CRSI offers a range of publications, including the Manual of Standard Practice, design guides, and technical resources. The 29th edition of the Manual is available on Amazon and through CRSI, providing updated standards for reinforced concrete construction. Additional design guides address topics like ACI 318 building code requirements, offering practical insights for engineers and contractors. Members receive discounted access to these resources, ensuring they stay current with industry developments and best practices in reinforcing steel applications.

10.3 Webinars and Training Programs

CRSI offers webinars and training programs to enhance industry knowledge and skills. These sessions cover topics like updates to the Manual of Standard Practice, best practices for reinforcing steel, and emerging trends in concrete construction. Professionals can attend regional conferences and online events to stay informed. CRSI members gain discounted access to these resources, ensuring they remain at the forefront of industry developments and standards. Regular updates and event schedules are available on the CRSI website.

Professional Development Opportunities

CRSI provides extensive resources for professional growth, including webinars, training programs, and certification opportunities. These tools help professionals enhance skills, stay updated, and advance their careers effectively.

11.1 CRSI Membership Benefits

CRSI membership offers exclusive benefits, including discounted access to the Manual of Standard Practice, free technical resources, and reduced rates for webinars. Members also gain networking opportunities through regional conferences and events. Additionally, CRSI members receive updates on industry standards and best practices, ensuring they stay informed about the latest advancements in reinforced concrete construction. These benefits collectively enhance professional development and foster industry collaboration.

11.2 Certification Programs for Professionals

CRSI offers certification programs designed to enhance expertise in reinforced concrete construction. These programs focus on mastering the Manual of Standard Practice, covering topics like steel reinforcement detailing and fabrication. Professionals gain in-depth knowledge of industry standards and best practices, ensuring compliance with current codes. Certification demonstrates a commitment to excellence, boosting career prospects and contributing to higher quality construction projects across the industry.

11.3 Networking Opportunities Through CRSI Events

CRSI events provide invaluable networking opportunities for professionals in the concrete construction industry. Conferences, webinars, and workshops allow members to connect with peers and industry leaders. These events foster collaboration, knowledge sharing, and exposure to innovative practices. By attending, professionals stay updated on the latest trends and advancements, enhancing their expertise and contributing to the evolution of the Manual of Standard Practice. Such interactions strengthen professional relationships and drive industry progress.

Benefits for Construction Professionals

The Manual of Standard Practice offers construction professionals enhanced knowledge, improved project efficiency, and access to industry trends, ensuring high-quality and compliant concrete construction practices.

12.1 Enhancing Knowledge and Skills

The Manual of Standard Practice serves as a comprehensive resource for construction professionals, enhancing their knowledge and skills in reinforced concrete construction. It provides detailed guidance on estimating, detailing, fabricating, and placing reinforcing steel, ensuring adherence to industry standards. By understanding the manual’s recommendations, professionals can improve their expertise in handling complex projects, staying updated on best practices, and applying innovative solutions. This expertise translates into better decision-making and the ability to tackle challenging scenarios effectively, fostering professional growth and competence in the field.

12.2 Improving Project Efficiency and Quality

The Manual of Standard Practice plays a crucial role in enhancing project efficiency and quality by providing clear guidelines for estimating, detailing, and fabricating reinforcing steel. Its standardized practices reduce errors and delays, ensuring compliance with industry specifications. By adhering to the manual’s recommendations, professionals can streamline workflows, optimize resource allocation, and maintain high-quality outcomes. This leads to improved project execution, reduced costs, and increased client satisfaction, ultimately elevating the overall standards of concrete construction projects.

12.3 Staying Updated on Industry Trends

The Manual of Standard Practice ensures professionals stay informed about the latest advancements in reinforced concrete construction. Regular updates, errata, and new editions reflect evolving industry standards and technologies. CRSI also offers webinars, training programs, and publications, providing continuous learning opportunities. By leveraging these resources, professionals can adapt to emerging trends, such as innovative materials and sustainable practices, ensuring their work remains aligned with current best practices and technological advancements in the field.

The Future of the Manual of Standard Practice

The manual will continue evolving, incorporating new standards for epoxy-coated bars and bar supports, ensuring it remains a vital resource for industry advancements and best practices.

13.1 Anticipated Changes in Upcoming Editions

Future editions of the Manual of Standard Practice are expected to focus on emerging materials and technologies, such as advanced epoxy-coated bars and stainless steel reinforcements. New sections may address modern design methodologies and sustainability practices in concrete construction. The manual will likely incorporate recent updates on bar supports, bend shapes, and corrosion-resistant bars. Additionally, it will reflect industry advancements in fabrication and placement techniques. These changes aim to align the manual with current trends, ensuring it remains a cornerstone for professionals in the field.

13.2 Emerging Trends in Reinforced Concrete Construction

The construction industry is embracing sustainability and innovative materials, with a focus on eco-friendly practices. High-strength, corrosion-resistant steels are gaining traction, reducing maintenance needs. Automation and 3D printing are revolutionizing fabrication and placement processes. Design methodologies now prioritize modular construction and adaptive reuse. Durability and longevity are key, with advancements in concrete mixes and reinforcing bar technologies. These trends align with global standards, ensuring reinforced concrete remains a vital, efficient, and sustainable building material for future projects.

The Manual of Standard Practice is a vital resource for the concrete construction industry, providing essential guidelines for reinforcing steel. It has evolved to address modern challenges, ensuring projects meet high standards of safety and durability. As the industry advances, CRSI remains committed to updating the manual, reflecting the latest innovations and best practices.

14.1 Summary of Key Takeaways

The Manual of Standard Practice is a cornerstone for the concrete construction industry, offering comprehensive guidelines for reinforcing steel. It covers estimating, detailing, fabrication, and placement, while addressing repair requirements. The 29th edition includes expanded illustrations and errata updates, ensuring alignment with current standards. Professionals benefit from its problem-solving insights and updated industry trends, making it an indispensable resource for enhancing project quality and efficiency. By adhering to its recommendations, practitioners can ensure compliance with best practices and advance their expertise in reinforced concrete construction.

14.2 Final Thoughts on the Importance of the Manual

The Manual of Standard Practice remains an indispensable resource for the concrete construction industry, providing unparalleled guidance on reinforcing steel practices. Its comprehensive updates, such as the 29th edition, ensure alignment with modern standards and address evolving challenges. By adhering to its recommendations, professionals can enhance project quality, efficiency, and safety. The manual’s enduring relevance underscores its critical role in advancing industry knowledge and fostering adherence to best practices, making it a cornerstone for both experienced professionals and newcomers alike.